Product Description

Product Description

PRODUCT DESCRIPTION

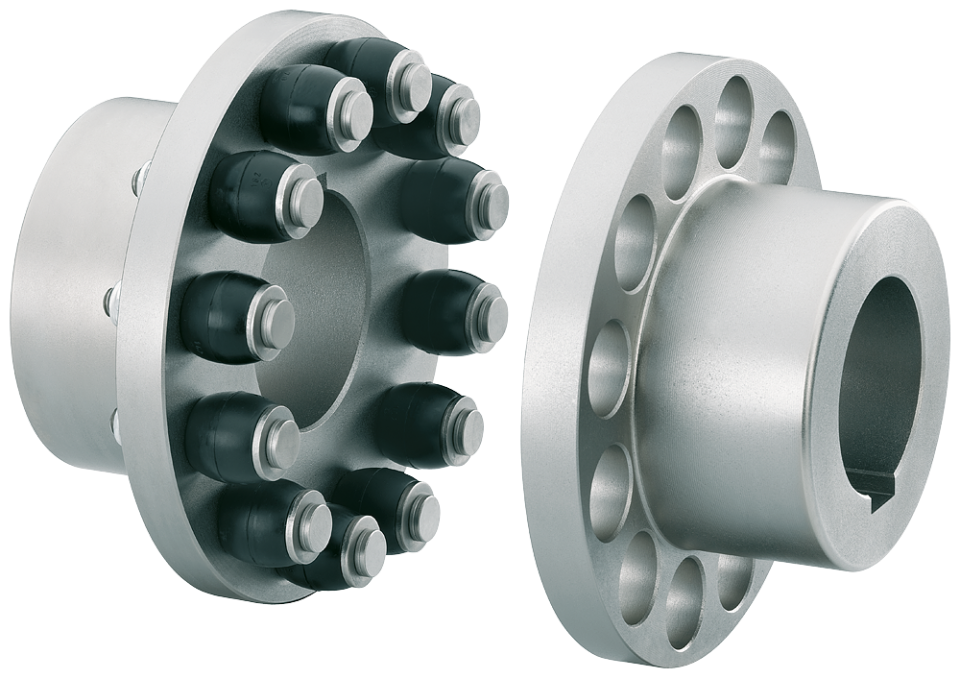

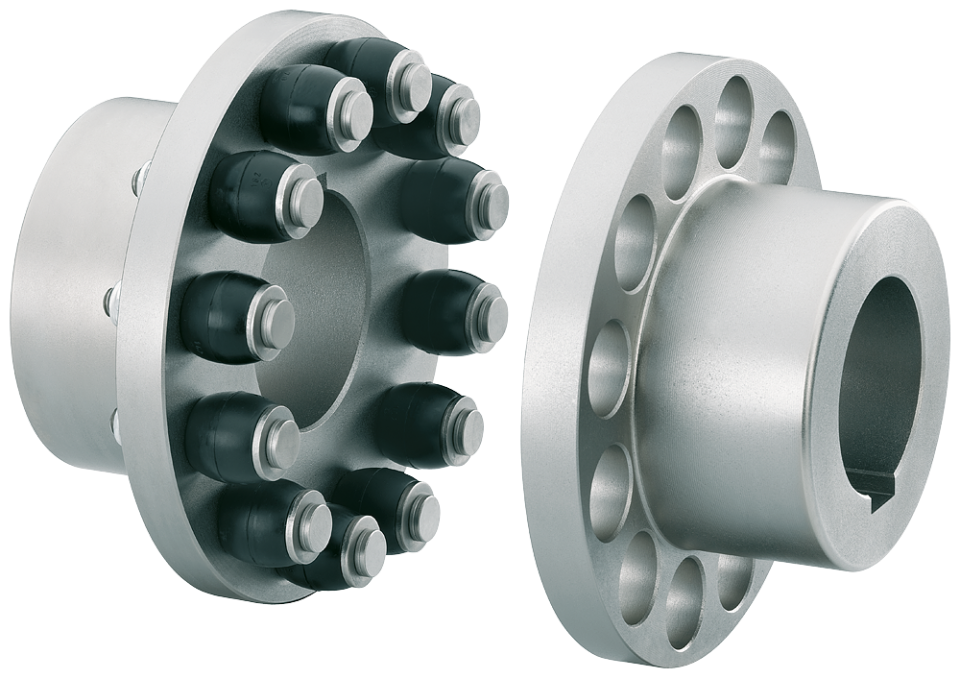

LT type shaft coupling with elastic sleeve and pin are widely used in various mechanical and hydraulic fields, can adapt positive and negative changeful start frequent occasions.

Printing machinery / Packing machinery / Wood-working machinery etc large-scale mechanical equipment.

Company Profile

COMPANY PROFILE

The predecessor of ZheJiang Jintiancheng Technology Co., Ltd. is ZheJiang Jintiancheng Machinery Special Casting Co., Ltd. The original company was established on November 25, 2016. The company has accumulated rich experience in casting technology and machining. According to the company’s development needs, it moved to the Re-manufacturing Industrial Park in Lugang Township, HangZhou City on October 15 2019.

Adhering to the concept of “science and technology leading, innovation driven, quality service, customer first”, the company is a comprehensive machinery manufacturing enterprise integrating centrifugal casting, solution treatment and machining. The company has a registered capital of RMB 15 million, covers an area of 90 mu, has more than 20 management personnel, more than 150 front-line employees, and 15 senior and intermediate technical personnel. The company’s main products include straight drums for centrifuges, cone drums, end shafts, mandrels, flanges and other pipe rings. The product materials are mainly austenitic stainless steel and duplex stainless steel. The company has strong production equipment and perfect testing equipment, which can provide customers with various customized and high-quality products.

Quality is the life of an enterprise, and integrity is the cornerstone of cooperation. ZheJiang Jintiancheng Technology Co., Ltd. Is sincerely willing to cooperate with you and develop together. looking CHINAMFG to your visit and guidance.

Certifications

CERTIFICATIONS

Processing Equipment

PROCESSING EPUIPMENT

Product Display

PRODUCT DISPLAY

Packaging & Shipping

PACKING AND SHIPPING

FAQ

FAQ

1. Q: How to give inquiry ?

A: Step 1, please tell us what weight ,dimension, material do you need please;

Step 2, Better help to provide the drawing with above-mentioned details please;

Step 3, When we have enough details, we may quote accordingly;

2 . Q: When will make delivery ?

A: Delivery Time

-Sample Order: 15 days after receipt of the full payment.

-Stock Order: 10 days after receipt of the full payment

-OEM Order: 60 days after receipt of the deposit.

3. After-sales Service

1 year warranty for all kinds of products;

If you find any defective accessories first time, we will give you the new parts for free to replace in the next order, as an experienced manufacturer, you can rest assured of the quality and after-sales service.

4. Payment

T/T, Western Union,Cash.

5. Transportation

Transported by DHL, UPS, EMS, Fedex,Air freight. Sea freight.

6. Do you support drop shipping?

Yes,your drop shipping is available. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 8-24 |

| Torque: | >80N.M |

| Bore Diameter: | 14mm |

| Speed: | 4000r/M |

| Structure: | Flexible |

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, pin couplings can be used in both horizontal and vertical shaft arrangements. These couplings are designed to accommodate angular misalignment, parallel misalignment, and axial movement, making them versatile for various shaft orientations.

In horizontal shaft arrangements, where the shafts are aligned on the same horizontal plane, pin couplings can efficiently transmit torque while allowing for flexibility to accommodate minor misalignments and shaft movements. The pins and flexible elements in the coupling enable angular displacement and radial flexibility, ensuring smooth power transmission even if the shafts are not perfectly aligned.

In vertical shaft arrangements, where the shafts are aligned on a vertical plane, pin couplings can also be used effectively. The coupling design allows for axial movement, which is crucial in vertical applications where the shafts may experience expansion or contraction due to thermal changes or other factors. The flexible nature of pin couplings allows them to handle these axial movements without compromising the coupling’s performance.

Whether in horizontal or vertical arrangements, pin couplings are commonly used in various industrial applications, including pumps, compressors, conveyors, and other rotating machinery. They are known for their simplicity, ease of installation, and ability to provide reliable power transmission while accommodating misalignment and shaft movement.

When using pin couplings in either arrangement, it is essential to ensure proper alignment and regular maintenance to maximize their performance and service life. Additionally, considering factors like torque requirements, operating conditions, and environmental considerations will help in selecting the appropriate pin coupling for a specific application.

Role of Pin Coupling in Reducing Downtime and Maintenance Costs

A pin coupling plays a crucial role in reducing downtime and maintenance costs in various mechanical systems and power transmission applications. Its design and features contribute to improved reliability and ease of maintenance, resulting in enhanced operational efficiency and cost savings. Here’s how pin couplings achieve these benefits:

1. Shock Absorption: Pin couplings are known for their ability to absorb and dampen shocks and vibrations generated during operation. By cushioning the impact of sudden loads or torque spikes, they protect the connected equipment from potential damage, reducing the frequency of unexpected breakdowns and downtime.

2. Misalignment Tolerance: Pin couplings can tolerate a certain degree of misalignment between shafts, such as angular and parallel misalignment. This flexibility allows for easier installation and alignment of equipment, saving time and effort during setup and reducing the need for precise alignment procedures.

3. Low Maintenance: Pin couplings are designed with simplicity in mind, often consisting of only two coupling halves connected by pins. This straightforward construction means fewer components that can wear out or require regular maintenance. Additionally, the flexibility of the pins helps reduce wear on the coupling and connected equipment, leading to longer maintenance intervals.

4. Easy Replacement: In the event of a failure or wear, pin couplings are relatively easy to replace compared to some other coupling types. The simplicity of their design allows for quick disassembly and reassembly, minimizing downtime during maintenance or replacement procedures.

5. Cost-Effective: The combination of low maintenance requirements and reduced downtime translates into cost savings for businesses. With fewer unexpected breakdowns and lower maintenance expenses, the overall cost of ownership for systems employing pin couplings can be more economical.

6. Reliability: Pin couplings are known for their reliability and durability. When properly selected and installed, they can provide long service life without frequent replacements, contributing to stable and consistent system performance.

By minimizing downtime, maintenance efforts, and associated costs, pin couplings are a preferred choice in various industrial applications. However, it is crucial to ensure that the pin coupling is correctly sized and installed, and regular inspections and maintenance are conducted to maximize its benefits and prevent premature failure.

Limitations and Disadvantages of Using Pin Couplings

While pin couplings offer various advantages and are suitable for many applications, they also have some limitations and disadvantages to consider:

- Misalignment Restrictions: Pin couplings can accommodate a certain degree of misalignment, but excessive misalignment can lead to increased wear and stress on the coupling components. They are not as effective at handling large angular or parallel misalignments compared to other flexible couplings like gear or elastomeric couplings.

- Less Damping Capacity: Pin couplings have limited damping capacity, which means they may not effectively absorb and reduce vibrations in the system. In applications where vibration damping is critical, elastomeric or flexible couplings may be more suitable.

- Noisy Operation: The rigid nature of pin couplings can lead to increased noise during operation, especially at high speeds or in applications with significant misalignment. This noise can be a concern in environments where noise levels need to be minimized.

- Higher Maintenance: Compared to maintenance-free couplings like certain types of elastomeric couplings, pin couplings may require more frequent inspection and maintenance. The pins and other components may experience wear over time and need replacement.

- Environmental Limitations: Some pin couplings may not be suitable for use in corrosive or high-temperature environments, depending on the materials used. Stainless steel or other corrosion-resistant materials can help mitigate this limitation.

- Size and Weight: In certain applications, the size and weight of pin couplings may be larger and heavier compared to other types of couplings. This can be a consideration in applications where weight is a concern or space is limited.

Despite these limitations, pin couplings remain a popular choice for many applications where their advantages, such as simplicity, durability, and cost-effectiveness, outweigh their disadvantages. It is crucial to carefully assess the specific requirements of the application and consider factors like misalignment, vibration, maintenance needs, and environmental conditions when selecting a coupling type.

editor by CX 2024-05-06

by

Tags:

Leave a Reply