Product Description

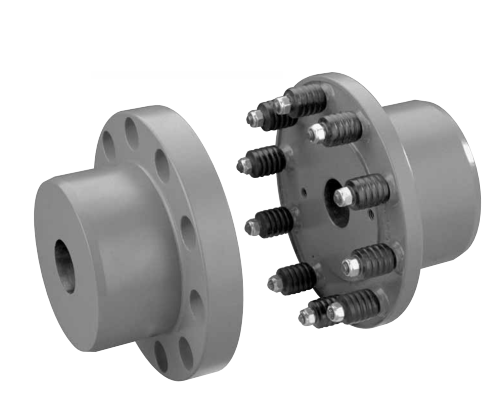

Medical Instrument Orthopedic Surgical External Fixation AO Rod Pin Coupling External Fixator

High precision CNC parts strictly according to customers’ drawing, packing and quality demands

Tolerance: +/-0.005mm

100% inspection during production and final to guarantee quality

10 years experienced engineers and workers

Fast and timely delivery. Speedy & professional service

Offer with professional consultations in designing of new parts to save cost.

Quality assurance in accordance to ISO9001

| Material | Stainless Steel | SUS201,SUS303,SUS304,SUS316,SUS416,SUS420,17-4PH,SUS440C | |

| Steel | Q235,C20,C45(K1045),1214,1215 | ||

| Copper | C36000(C26800),C37700(HPb59),C38500(HPb58),C27200(CuZn37),C28000(CuZn40/H62),C3604, C51000, C52100, C54400,CuSn8 | ||

| Alumina | AL2571,AL5754(Almg3),AL5083,AL6061,AL6063,AL5052,AL7075 | ||

| Alloy Steel | SCM435,10B21 | ||

| Plastic | PA6,PA66,PP,PC,POM,FR4,ABS,Acrylic | ||

| Machining Processes | CNC 3-axis, 4-axis machining, CNC milling, CNC turning, CNC Lathe High precision 5-Axis turning-milling combined machining, CNC milling and turning, drilling, grinding, stamping, tapping, bending, laser cutting, welding etc |

||

| Finish | Heat treatment, powder coating, electroplating, spraying, painting, polishing, deburring, wire drawing/brushed, anodizing, chrome plating, nickel plating, tin plating, silver plating, gold plating, galvanizing, blackening etc. | ||

| Dimensions | Customized | ||

| Tolerance | ±0.005mm | ||

| Drawing Format | PDF/JPEG/AI/PSD/CAD/Dwg/Step/LGS | ||

| MOQ | Negotiable | ||

| QC Policy | 100% inspection and random inspection before shipment, with QC passed label | ||

| Stardard | Materials and surface treatment comply with RoHS/Reach Directives | ||

| Testing Equipments | CMM, Projector, Pull Tester, Automatic Optical Inspector, Salt Spray Tester, Durometer, Tensile Machine, height gauge, micrometer, plug gauge, thread Gauges, digital caliper and etc. | ||

| Application | Automotives, Optical instrument, medical device, industrial machine, automobile, electric appliance, robot, computers, tele-communication, electronic device, digital communication, UAV, aerospace, bicycle, pneumatic tools, hydraulic and other industries, | ||

| Packaging | PE bags or bubble bags, boxes, cartons, pallet, standard carton or plastic tray, sponge tray, cardboard tray or as per customers’ requirements | ||

| Trade Terms | EXW, FOB, CIF, As per customers’ request | ||

| Payment Terms | Paypal or Western Union for sample orders; Larger amount by T/T with 30% as deposit,70% before shipment | ||

| Delivery Time | Within 15-20 working days after deposit or payment received | ||

| Shipping Ports | FOB HangZhou, FOB HangZhou, FOB Hongkong | ||

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Quality Guaranteed |

|---|---|

| Condition: | New |

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized: | Customized |

| Material: | Stainless Steel 317 |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Accommodate High Torque and High-Speed Applications?

Pin couplings are versatile and robust, making them suitable for a wide range of applications, including those involving high torque and high-speed requirements. However, the specific design and construction of the pin coupling will determine its capacity to handle such demanding conditions.

The ability of a pin coupling to accommodate high torque depends on factors such as the material used, the size and number of pins, and the overall design. High-quality pin couplings are often made from strong and durable materials like alloy steel, which allows them to withstand significant torque loads without failure or deformation.

Similarly, the capability of a pin coupling to handle high speeds depends on factors such as the balance of the coupling and the precise manufacturing of the pins and hubs. Properly balanced pin couplings can operate at higher speeds without generating excessive vibration or causing premature wear.

When selecting a pin coupling for high torque and high-speed applications, it is essential to consider the following:

- Design and Construction: Opt for pin couplings with a robust and well-engineered design to handle the expected torque and speed requirements.

- Material: Choose pin couplings made from high-quality materials known for their strength and fatigue resistance.

- Size: Select an appropriate size of pin coupling that can accommodate the torque and speed expected in the application.

- Manufacturer’s Ratings: Refer to the manufacturer’s specifications and torque-speed curves to ensure the coupling meets the desired performance criteria.

By carefully considering these factors and choosing a pin coupling designed for high torque and high-speed applications, you can ensure reliable and efficient power transmission in demanding industrial settings.

Usage of Pin Couplings in Applications with Varying Operating Temperatures

Pin couplings are versatile and can be used in a wide range of operating conditions, including applications with varying temperatures. The performance of pin couplings at different temperature levels depends on the materials used in their construction and the specific design features. Here’s how pin couplings handle varying operating temperatures:

1. Material Selection: Pin couplings can be manufactured using different materials, including steel, stainless steel, alloy steel, and various heat-treated materials. The choice of material depends on the application requirements and the temperature range the coupling will be subjected to. Some materials are suitable for high-temperature applications, while others are more suitable for low-temperature conditions.

2. Heat Dissipation: The simple and open design of pin couplings allows for efficient heat dissipation. As the coupling operates, any heat generated due to friction or other factors can easily dissipate into the surrounding environment. This helps in maintaining a stable operating temperature and prevents overheating of the coupling and connected equipment.

3. Lubrication: Proper lubrication is essential for the smooth operation of pin couplings, especially in applications with high temperatures. Lubricants help reduce friction and wear between the mating surfaces, ensuring that the coupling functions optimally even in elevated temperature conditions.

4. Thermal Expansion Considerations: Pin couplings must be designed with thermal expansion in mind. When the operating temperature increases, the materials may expand, and the coupling should have sufficient clearance or play to accommodate this expansion without causing binding or interference.

5. Temperature Limits: While pin couplings can handle a wide range of temperatures, there are limits to the extremes they can tolerate. Excessive heat can lead to degradation of the coupling material, premature wear, or reduced performance. It’s essential to choose a pin coupling that is rated for the specific temperature range of the application.

6. Insulation: In certain cases, pin couplings may need additional insulation to protect against extreme temperature variations or to prevent heat transfer to sensitive components nearby. Insulation can be achieved using materials with low thermal conductivity or by incorporating insulating coatings or barriers.

When selecting a pin coupling for an application with varying operating temperatures, it’s crucial to consider the specific temperature range, the type of materials used in the coupling’s construction, and any additional factors that may impact its performance. Following the manufacturer’s guidelines and ensuring proper maintenance will help ensure the pin coupling operates effectively and reliably across the expected temperature range.

Can Pin Couplings Handle Misalignment Between Shafts?

Yes, pin couplings are designed to accommodate a certain degree of misalignment between shafts in rotating machinery. They are considered flexible couplings, which means they can provide some degree of angular, parallel, and axial misalignment capability.

Pin couplings typically consist of two hubs, each connected to a shaft, and a central sleeve with pins that transmit torque between the hubs. The pins allow for a limited range of movement, which helps to compensate for slight misalignments between the shafts.

The angular misalignment capacity of a pin coupling is achieved through the bending of the pins. When the shafts are misaligned at an angle, the pins on one side of the coupling experience bending while those on the opposite side are in tension. The pins are designed to withstand these bending and tension forces within their elastic limits, ensuring proper functioning and longevity of the coupling.

Similarly, the pins can accommodate parallel misalignment by sliding within the pin holes of the coupling’s central sleeve. This sliding action allows the hubs to move slightly relative to each other, compensating for any offset between the shafts.

However, it is essential to note that pin couplings have limitations in terms of the amount of misalignment they can handle. Excessive misalignment beyond their specified limits can lead to increased wear on the pins and other coupling components, reducing the coupling’s effectiveness and potentially causing premature failure.

While pin couplings are suitable for applications with moderate misalignment requirements, they may not be the best choice for applications with significant misalignment or where precise alignment is critical. In such cases, more flexible couplings like gear or elastomeric couplings may be more appropriate.

Overall, when considering the use of pin couplings, it is essential to carefully evaluate the specific misalignment requirements of the application and select a coupling that can adequately accommodate those misalignments while ensuring reliable and efficient power transmission.

editor by CX 2024-04-24

by

Tags:

Leave a Reply